For sailing enthusiasts, renovating or restoring a boat is much more than just a technical project; it’s a real adventure, a quest to restore life and splendor to a fellow traveler.

Whether it’s a classic sailboat or a more modern unit in need of a facelift, every owner, shipyard or architect faces a major challenge: finding parts and accessories that combine performance, durability and aesthetics. This is where standard hardware and fittings show their limits, leaving room for custom expertise and know-how.

For over 15 years, WoodSpars has set the standard in France and internationally for the manufacture of masts for sailing yachts. Building on this experience, our workshop has developed cutting-edge expertise in the design and manufacture of custom accessories, responding to the most complex problems encountered in renovation and restoration projects.

The Renovation Puzzle: When Standard Parts Are No Longer Enough

Restoring a sailboat is often a journey fraught with pitfalls. The first difficulty, and not the least, is finding replacement parts, especially for older boats. Original parts are no longer manufactured, and the dimensions of modern equipment rarely correspond to period configurations. What’s more, the quality of materials has evolved, and what was standard 20 years ago can now be a source of weakness.

Problems frequently encountered by our customers include :

- Wear and corrosion: The marine environment is unforgiving. Salt, humidity and constant stress inevitably degrade metal parts, even stainless steel, if the grade is unsuitable.

- Breakage: Fittings that are undersized or tired from years of service can fail in mid-ship, with serious consequences such as dismasting.

- Lack of performance: Aging fittings can impair performance, making manoeuvres more difficult and less precise.

- Aesthetics: For owners of classic sailboats or exceptional yachts, preserving the harmony and authenticity of the boat is paramount. Standard parts, often mass-produced, distort the unique character of these vessels.

Faced with these challenges, customization is not a luxury, but a necessity. It guarantees perfect adaptation, enhanced safety and respect for your yacht’s identity.

The Woodspars Solution: Made-to-measure and Excellence in Materials

At Woodspars, we don’t just replace a part. We analyze it, understand its function and constraints, and reinvent it to make it more reliable, more efficient and perfectly integrated into your boat. Our workshop, specialized in 316L stainless steel and galvanized steel, is at the heart of our expertise.

316L stainless steel: the guarantee of unrivalled strength

- Wear and corrosion: The marine environment is unforgiving. Salt, humidity and constant stress inevitably degrade metal parts, even stainless steel, if the grade is unsuitable.

- Breakage: Fittings that are undersized or tired from years of service can fail in mid-ship, with serious consequences such as dismasting.

- Lack of performance: Aging fittings can impair performance, making manoeuvres more difficult and less precise.

- Aesthetics: For owners of classic sailboats or exceptional yachts, preserving the harmony and authenticity of the boat is paramount. Standard parts, often mass-produced, distort the unique character of these vessels.

Faced with these challenges, customization is not a luxury, but a necessity. It guarantees perfect adaptation, enhanced safety and respect for your yacht’s identity.

A workshop dedicated to your projects

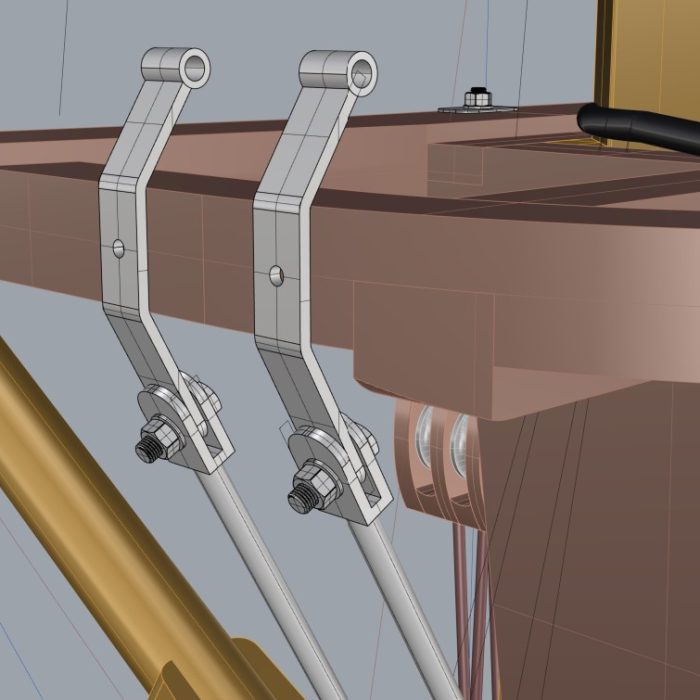

Our skilled team masters the art of working metal to bring unique pieces to life. From laser cutting to precision welding, every step is carried out to the highest standards of quality. We design and manufacture a full range of custom fittings to meet your every need.

Focus on Our Achievements : A complete set of fittings for your rig

The integrity of your mast and standing rigging depends directly on the quality of each component. Here’s an overview of the customized solutions Woodspars offers to optimize and enhance the reliability of every component of your sailboat.

Masthead and top anchors

The masthead is a key component, subject to considerable stress. We manufacture mastheads custom-made high shroud anchorsand halyard leads halyard leads halyard sheaves halyard sheaves and backstay outlets adapted to your sail plan. For racing or fast cruising yachts, we integrate high-performance solutions such as the mainsail hook hook or genoa hookto guarantee secure locking and an optimal sail profile.

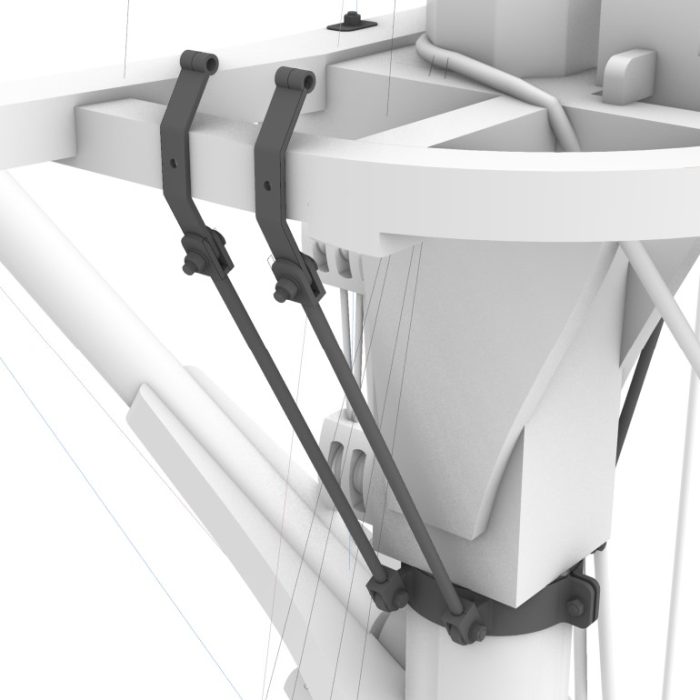

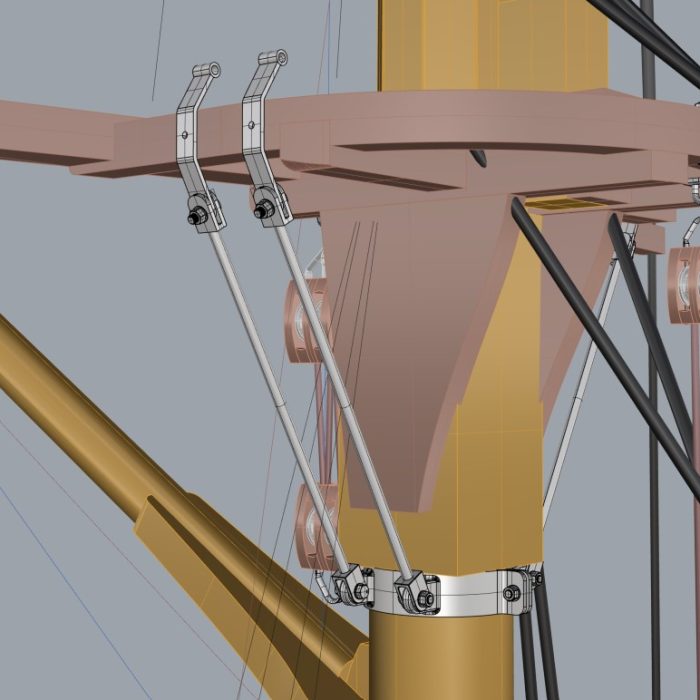

Boom Bars and Intermediate Bindings

The spreaders are essential to the mast’s stability. We design spreader brackets and lower shroud anchors to ensure perfect load distribution. Our bespoke adjustable bellcranks enable fine, reliable adjustment of rigging tension. We also manufacture sturdy topsail fittings formore complex rigs.

Mast foot and boom joint

The connection between mast and deck is a critical area. A tailor-made mast step, designed to fit the root of your boat perfectly, is a guarantee of safety. The articulation with the boom, the gooseneck, is a part that we manufacture with particular care to guarantee flawless strength and fluidity of movement.

Boom and spinnaker pole fittings

The boom is also subject to heavy stress. We make all boom fittings, including boom sheet anchors and boom reefing systems, designed to simplify and secure maneuvering. Spinnaker pole fittings are also custom-made to suit your spar and sailing style.

Mast Fittings and Finishes

To complete the equipment, we manufacture and install mast winches, halyard leads, spinnaker and genoa blocks, as well as fittings rails. Every part is designed for maximum ergonomics and efficiency.

Beyond Fittings: A Global Approach to Your Rig

Our expertise doesn’t stop at boiler making. As mast manufacturers, we have a complete vision of your yacht’s needs. We can advise and supply you with the most suitable ropes and cables, and apply high-protection varnishes to all your wooden spars, ensuring a flawless finish and long-lasting protection.

The Woodspars Promise: Experience, Quality and International Delivery

Choosing Woodspars means opting for peace of mind. It’s the guarantee of work carried out to the highest standards, by enthusiasts who understand your requirements.

- Recognized experience: More than 15 years at the service of sailors and yachting professionals.

- Made-to-measure quality: unique parts designed for your boat, combining robustness and elegance.

- Impeccable finish: Because details make all the difference, we take extreme care in the finish of every piece leaving our workshop.

- Global expertise: From mast to fittings, varnish and ropes, we offer you a complete solution.

- International delivery: Whether your boat is in a French port or on the other side of the world, we organize the delivery of your parts with the utmost rigor.

Your renovation or restoration project deserves the best. Don’t let faulty or unsuitable fittings compromise your safety and sailing pleasure.

Contact the Woodspars team today. Let’s discuss your project, your problems and your desires. We’ll be delighted to put our expertise at your service, to offer you a personalized quote and tailor-made solutions that will make your yacht a benchmark of elegance and reliability.

Need more information? Looking for a quote? Let’s discuss your projects!

Frequently Asked Questions : Your renovation projects and our customized solutions

Do you have a restoration or renovation project for your sailboat? Do you have questions about the manufacture of custom fittings? Woodspars, a French manufacturer of masts and fittings, answers your most frequently asked questions here.

Why opt for custom hardware when renovating my sailboat?

Opting for custom fittings is often a necessity, not a luxury, when renovating a sailboat. Standard parts rarely correspond to the dimensions and constraints of older boats or specific constructions. Custom-made fittings guarantee a perfect fit, maximum safety by replacing a tired part with a new, optimized one, and preserve theaesthetic harmony of your boat. It’s the assurance of a part designed to last, perfectly integrated into your rig.

I can't find the original parts for my old boat. What do you suggest?

This is a classic problem we encounter on a daily basis. Our workshop specializes in the identical reproduction orimprovement of existing parts. Even if your hardware is worn or broken, we can recreate it from the original model. If you have drawings or diagrams, we can also work from these to produce a new part that meets the specifications of your sailboat.

What type of stainless steel do you use and why is it suitable for the marine environment?

For all our fittings and boiler parts, we use only316L stainless steel, also known as marine stainless steel. Its composition, enriched with molybdenum, gives it far superior resistance to pitting corrosion, particularly that caused by the chlorides present in seawater. Unlike inferior stainless steels, 316L guarantees exceptional longevity and rock-solid reliability for the critical parts of your fittings.

What fittings can you custom-make?

Our production capacity is extensive. We manufacture a complete set of fittings for rigging, including :

- For the mast: mastheads, shroud anchors, halyard leads and sheaves, spreader brackets, mast feet, gooseneck, mast winches…

- For the boom: anchor fittings, reefing lines, clew fittings…

- For running rigging: spinnaker and genoa blocks, halyard leads, hooks…

- Specific parts: backstay outriggers, adjustable horns, jib fittings, spinnaker pole fittings and any other metal parts on request.

Is your workshop based in France and do you deliver internationally?

Yes, our manufacturing workshop and boiler works are located entirely in France, which means we can guarantee rigorous quality control at every stage. We’re very proud of this French know-how. We are used to working with an international clientele, and we guarantee secure delivery worldwide, whether you’re a private customer in the Mediterranean, a shipyard in the Caribbean or an architect in New Zealand.

How can I get a quote for one or more custom fittings?

The process is simple. The best way is to contact us directly by telephone or via the contact form on our website. To enable us to draw up an accurate quotation, please provide us with as much information as possible: photos of the part to be replaced, precise dimensions, plans if you have any, the model of your boat and a description of your requirements. Our engineering department will analyze your request and propose a costed solution as soon as possible.

WoodSpars™, manufacture of glued laminated timber masts for the boating industry, various logs for the building industry, class IV posts and stakes for green spaces.